ANT server functionality: in detail

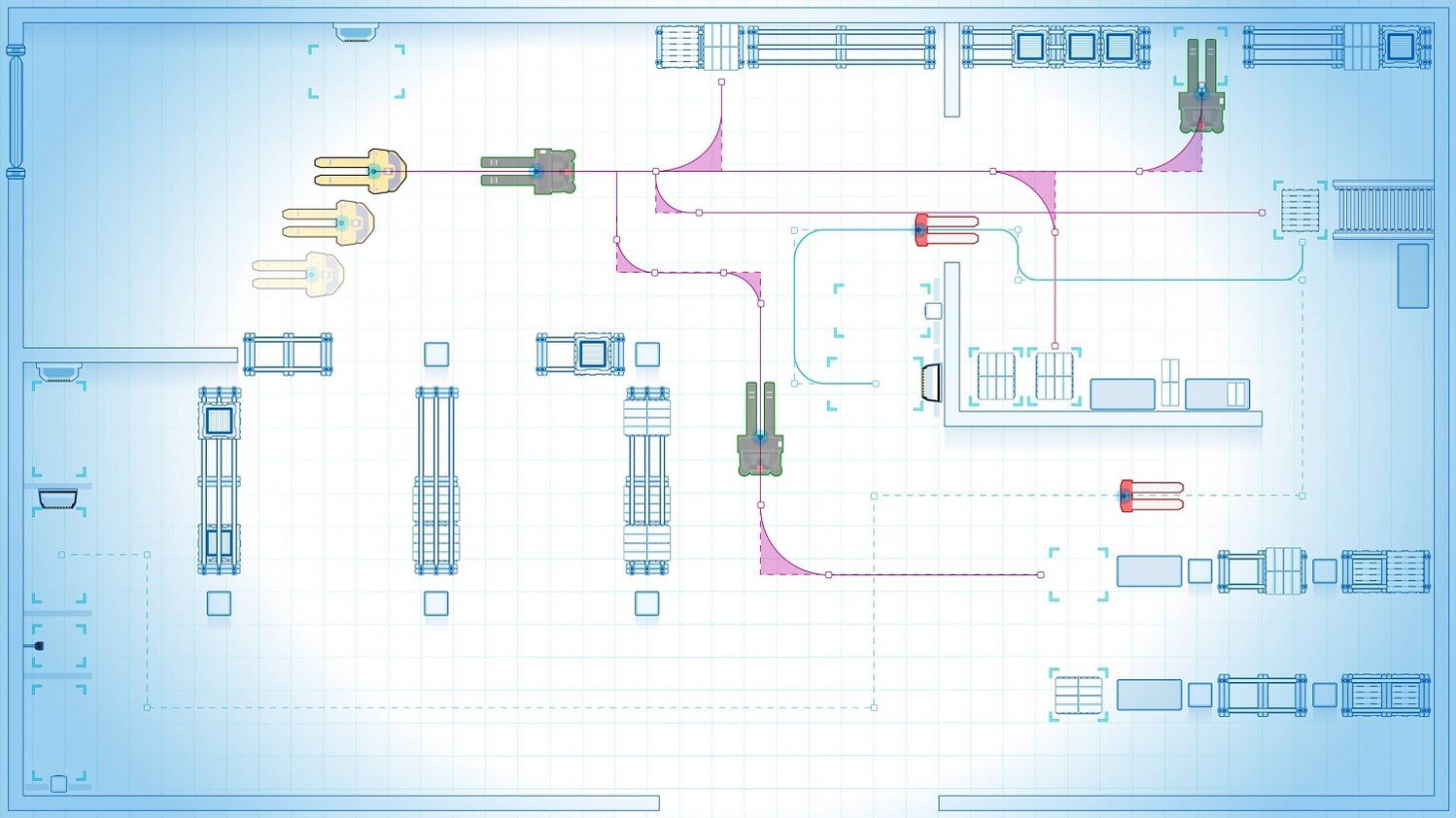

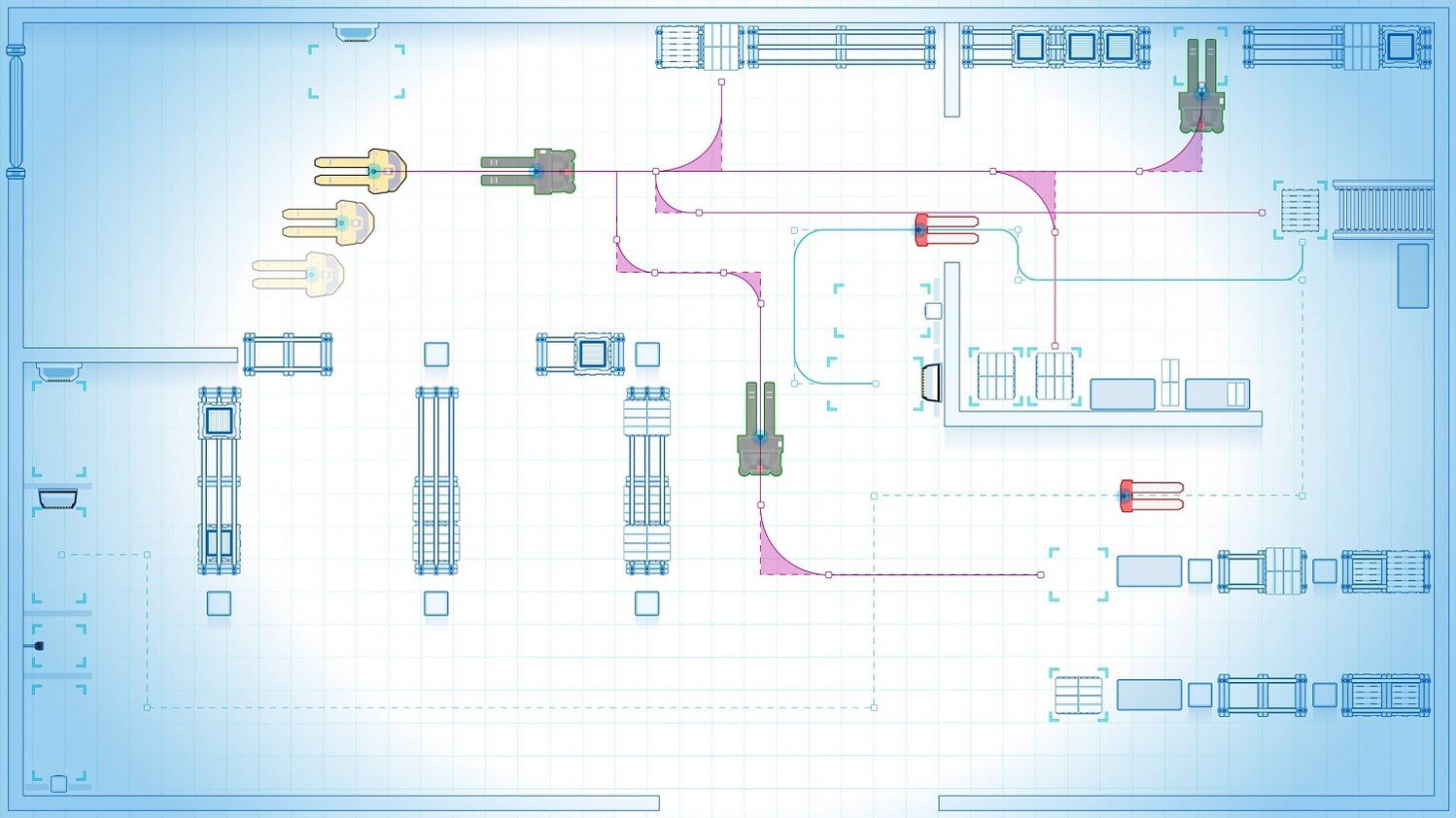

When working with a fleet of ANT driven vehicles, ANT server works off the site map created in BlueBotics’ ANT lab configuration software, dispatching missions to whichever robot (AGV/AMR) is the most efficient choice.

Mission scheduling

ANT server's intelligent scheduler selects and deploys the right vehicle for each mission, based on user-configurable parameters. This includes making sure the vehicle can fit in the space available and carry the payload requested.

Missions can be requested in several ways:

- Via your existing business software using ANT server’s dedicated API.

- Via an input from any type of PLC that supports OPC UA or Modbus communication: for example, when a sensor detects a pallet, or at the push of a button.

- Via ANT monitor (ANT server’s web interface).

Missions can be cancelled manually, for example via the ANT monitor web interface or an API request. They can also be cancelled automatically, for example in case of vehicle issues, via an API request, or via a push button/vehicle HMI screen.

Real-time visualization & monitoring

Missions can be visualized, in real-time, using ANT server’s intuitive web interface, ANT monitor. This visualization is also useful when testing new installations.

ANT monitor includes:

- Mission execution visualization

- Error visualization

- System statistics

- ANT monitor can also be used to visualize project simulations.

ANT monitor also features four levels of user access, with the option to connect via Active Directory.

Simulation

To ensure an AGV or AMR project runs seamlessly from day one, there is ANT server’s sophisticated Simulator tool.

Using the digital twin created in ANT lab, ANT server Simulator allows your vehicle integrator to run and test your project using virtual vehicles first – simulating everything from individual AGV missions to full-scale fleet operations featuring multiple vehicles picking and dropping, charging, devices and more.

This ability is useful at the project planning stage, as it can help your vehicle supplier or third-party integrator precisely estimate how many vehicles your site will require. Plus, this simulation function enables your vehicle supplier to test and optimize numerous other parameters, such as:

- The number of missions required

- The optimal charging strategy

- The most efficient vehicle speeds

- Traffic management

- Plus, your integrator can use ANT server’s Simulator to stress-test any software integrations they have programmed (e.g. ANT server -> WMS/MES/ERP).

Traffic control

ANT server’s intelligent traffic manager seamlessly coordinates the movement of different vehicles at locations such as intersections, doors, elevators etc. This ensures intersections are never blocked, working on a ‘first-come, first-served’ basis.

This deadlock-free traffic control is fully automatic, by default, and it can also be configured to suit your site’s specific needs.

Battery charge management

ANT server receives battery status data from every vehicle in its fleet by default. When a vehicle’s battery falls to a pre-determined (and user-configurable) level, ANT server recognizes this and immediately determines when, and where, the vehicle must go to recharge its battery.

ANT server includes three ‘charging modes’ by default. Vehicles can be set to charge whenever idle (opportunity charging), when their battery charge level falls lower than the fleet’s average, or when a vehicle’s individual battery level is low (under 20% by default).

If a vehicle is between missions and does not need to recharge, it goes to the nearest parking space by default.

Interfacing with equipment & software

ANT server can communicate with on-site equipment – such as conveyors, elevators, automatic doors and more – by managing the flow of requests and responses between vehicles and an external device’s PLC. This communication is programmed via ANT software’s Devices function, using either Modbus or OPC UA protocols.

Missions can also be triggered and monitored via your standard business software (WMS/MES/ERP etc.) thanks to ANT server’s REST API. Once programmed, this allows your team to manage your AGV operation via a familiar interface.

Multi-brand fleet management

ANT server is a cross-platform solution, built with vehicle interoperability in mind. It selects and deploys the right vehicle for each mission, seamlessly coordinates vehicles at intersections, and provides operators with a complete overview of their fleet in real-time.

ANT server is capable of natively managing over 150 different models of ‘ANT driven’ AGV and AMR, no matter what a vehicle’s type.

If your automation project requires a specific vehicle type that is not available within the ANT driven ecosystem of vehicles, ANT server can also manage non-ANT driven vehicles that are compatible with the VDA 5050 interoperability standard.

Note: The functionality offered by this standard at the time of writing is below that of ANT server’s native capabilities, and additional programming time and cost is required to integrate such VDA 5050 vehicles into a fully mixed fleet. Contact us to learn more.

Full statistics & reporting

To assess and optimize how an AGV/AMR installation is performing, ANT server includes full statistics and reporting.

These statistics cover important parameters such as:

- Mission success rates – useful for checking effectiveness of the installation and any modifications made

- Vehicle occupation times – useful for optimizing the number (and type) of vehicles in use

- Errors and alarms (i.e. displayed on a heat map) – useful for identifying problematic vehicles and/or stations

- Average battery charge levels – useful for optimizing a project’s charging strategy

- And more...